Mono-material paper tubes are a smart shift in packaging. They use one material – paper or cardboard – from start to finish. This setup makes them fully recyclable and practical for brands that want real sustainability without cutting corners on protection.

I've worked with packaging solutions for over 10 years, helping small brands switch to better options. At Earthycores, we specialize in custom paper tubes, and mono-material design is at the heart of what we do. Let me break it down based on hands-on experience and what we've learned from producing thousands of these tubes.

A mono-material paper tube is built entirely from paper or cardboard layers. No plastic liners, no foil barriers, no mixed materials. Every part – inner wall, structural layers, outer label – stays the same throughout.

From production experience, this means the tube is spiral-wound like a premium composite can but made purely from paper components. The result is packaging that can go straight into paper recycling without confusion.

We use 100% paper-based materials sourced from certified recycled content. Cardboard provides structure, durability, and printability while remaining environmentally responsible.

Paper arrives in large rolls

It is slit into precise strips

Strips are spiral-wrapped around a mandrel

Water-based adhesives bond the layers

Wall thickness can be adjusted from lightweight designs for cosmetics to heavy-duty protection for candles or glass containers.

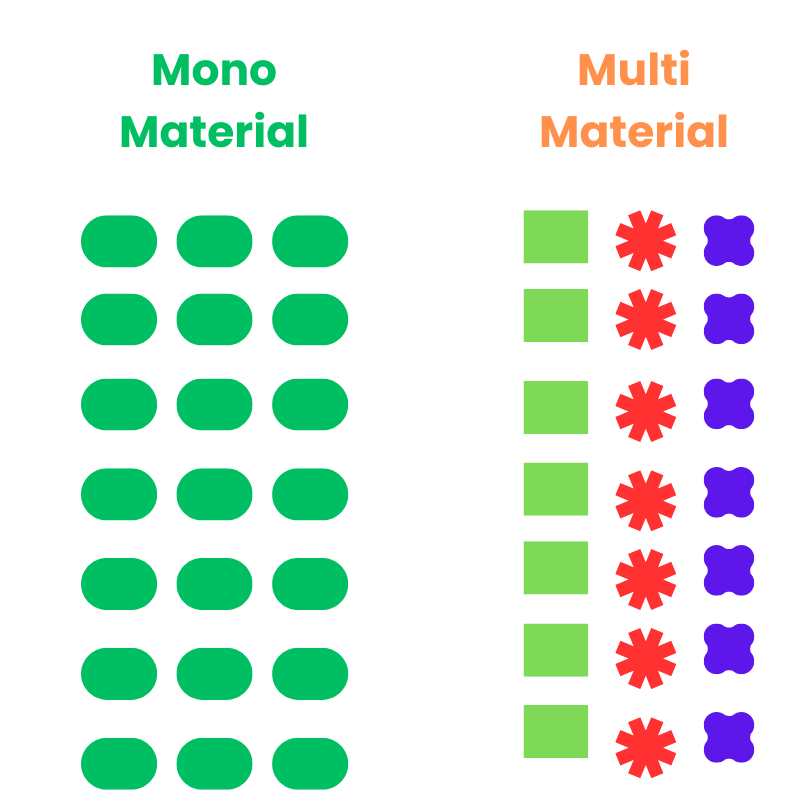

Mixed-material packaging is difficult to recycle because layers must be separated. Mono-material tubes eliminate this issue, allowing cleaner recycling streams and supporting genuine sustainability claims.

Brands also benefit from simpler labeling, regulatory compliance, and consumer trust when packaging is clearly recyclable.

Cosmetics: Balms, deodorants, solid perfumes

Food: Tea, coffee, spices, snacks

Health: Supplements and powdered products

Bath & Body: Bath salts and soap bars

Retail & Gifts: Candles, apparel accessories

Recyclable coatings improve resistance to humidity and light moisture exposure while keeping the tube paper-recyclable.

Spiral winding creates multiple compression-resistant layers, protecting products during shipping and retail handling.

Dense paper layers slow oxygen transfer and help preserve dry goods like tea and coffee.

Paper tubes are lighter than glass or rigid plastic, reducing shipping costs and improving the unboxing experience.

Select recycled paper stock

Cut and prepare paper strips

Spiral wind layers with water-based glue

Cut to size and print branding

Add paper lids or inserts

Perform quality checks

Mono-material paper tubes support high-quality printing, embossing, and premium finishes. Brands can include recycling instructions and eco-labels directly on the packaging.

While initial costs may be higher than plastic, savings appear in shipping, brand perception, and regulatory readiness. Consumers increasingly prefer sustainable packaging, which can influence purchasing decisions.

Mono-material tubes are ideal for dry and solid products. Liquids require an internal container, and extremely humid environments may need additional protection.

Packaging regulations and consumer demand are pushing brands toward recyclable mono-material solutions. Innovations in fiber strength and natural coatings continue to improve performance.

From cosmetics to specialty foods, brands continue switching to mono-material tubes because they combine sustainability, protection, and premium shelf appeal.

Yes. They are made entirely from paper-based materials and can be recycled in normal paper recycling streams.

They work very well for dry foods like tea, coffee, spices, and snacks by offering protection from air and moisture.

Yes. Multi-layer spiral construction provides strength and crush resistance for shipping and retail handling.

Yes. They support full-color printing, embossing, and premium paper finishes for strong brand presentation.

No. They are best for dry and solid products. Liquids r